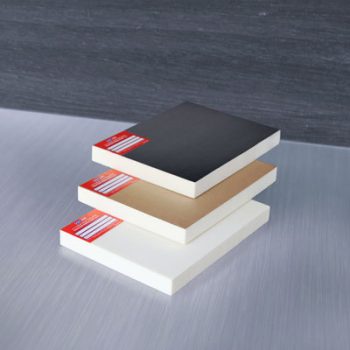

Polyurethane(PU) / Polyisocyanurate(PIR) foam

POLYFOAM Polyurethane(PU) and Polyisocyanurate(PIR) and foam is made by mixing a liquid Polyol with a liquid polymeric isocyanate known as MDI(Methylene Diphenyl di-Isocyanate)in the presence of a blowing agent and other additives. The mixed components then react exothermally to form a rigid thermosetting polymer and since the blowing agent evaporates during this exothermic reaction a rigid closed cell low density insulation product is created.

Excellent insulation is achieved because the gas trapped within the closed cell structure has a very low thermal conductivity and there is minimal heat conduction through the solid cell walls due to the low density, where approximately 97% of the volume of the foam is trapped gas.

General Description

POLYFOAM Polyurethane(PU) and Polyisocyanurate(PIR) rigid foams are one of the most efficient thermal insulation materials enabling effective energy savings with minimal thickness.

POLYFOAM Polyisocyanurate (PIR) foam is manufactured in similar way to standard polyurethane. POLYFOAM Polyisocyanurate (PIR) has all the characteristics and advantages of rigid polyurethane foam but offers greatly increased resistance to burning and spread of flame and is able to withstand temperatures up to 1490C. when subjected to fire the outer surface of the foam forms a strong carbonaceous layer which retards further flame spread and penetration. for ease of identification, POLYFOAM PIR is colored Light yellow.

POLYFOAM PIR offers better insulation performance, improved fire resistance, and enhanced moisture resistance compared to PU. POLYFOAM PIR/PU is colored natural color as Light yellow.

Application

POLYFOAM Polyurethane(PU)/ Polyisocyanurate(PIR) rigid foams are an important role of thermal insulation used in a wide variety of industrial and commercial applications, including air conditioning, refrigeration, food and beverage, pharmaceutical, petrochemical, and liquefied natural gas (LNG).

POLYFOAM Polyurethane(PU)/ Polyisocyanurate(PIR) rigid foam is also used as a core material for composite panels in applications like transportation, building construction, and temporary mobile shelters. These panel core foams are still PIR, but most are made at the lower index range. These low-index foams are better suited for panel core because of better impact resistance, adhesion, and strength properties.

Common applications :

- Industrial pipe insulation, including elbow and fittings

- Commercial chilled water line and tank insulation

- Tank and vessel insulation

- Core material for GRP applications

- Core material for architectural and structural panels

- Insulation for shipping containers, trucks, or railcars

- Core material for factory-built panelized constructions

- Flat or tapered board stock for floor & roof insulation

- Foam slab insert for aluminum sections, steel doors, and windows

- PU/PIR blocks for tooling and model making or for customized structures and constructions

- Constant thermal performance- reducing cooling cost for the life time of a building.

- Dimensionally stable- in range of service temperature (-200 0C – +1200C)

- Easy to install- Saving time, reducing labor costs and making health and safety regulations easier to meet.

- Closed cell structure and excellent moisture resistance- high levels of closed cells offering high levels of buoyancy.

- Chemical resistance – Provides excellent resistant to many common chemical solvents and oils.

- High strength to weight ratio-strong & Rigid

- Fire performance- POLYFOAM PUR/PIR is usually used at lower thicknesses than other insulants, so that their heat or fuel contribution to a fire is low compared to other thicker insulating materials

- Enhanced compressive and tensile strength at cryogenic temperatures make it resistant cracking

- PU/PIR foam slabs for boat manufacturing

Availability

POLYFOAM Polyurethane(PU) and Polyisocyanurate(PIR) rigid foams are a wide selection of insulating options, including Slabs/Boards, and Pre-formed pipe sections available as segments for larger sizes, pipe fittings, include elbows, tees, valve covers, etc.

Products may be un-faced or faced with reinforced aluminum foil (Class ‘1’) or (Class ‘O’), Craft paper or fiber tissue.

POLYFOAM standard sizes:

POLYFOAM slab sizes are;

- 2400mm(L) X 1200mm(W) X 8mm – 450mm

- 2000mm(L) X 1000mm(W) X 8mm – 750mm

- 1500mm(L) X 750mm(W) X 8mm – 800mm

POLYFOAM Pipe insulation:

POLYFOAM pipe sections and fitting ranges from an outer diameter (OD) 17mm onwards and length up to 1meter in various thickness and segments.